Constructive bonding with double-sided self-adhesive die-cut parts made from adhesive tapes

Advantages of self-adhesive technology in automotive and vehicle construction, the electronics and plastics industries, and mechanical engineering

What advantages do self-adhesive die-cut parts offer for structural bonding compared to other joining methods?

Double-sided adhesive die-cut parts are versatile and adaptable, quick to process and can be easily integrated into efficient processing workflows. The combination of high-performance adhesive tape materials and state-of-the-art die-cutting technology opens up a wide range of applications in all industrial sectors.

When materials need to be joined together, bonding with die-cut parts made from self-adhesive tapes is often the perfect solution, as the properties of the materials to be joined remain completely unchanged.

Our die-cut parts can be developed individually for your process with precisely tailored dimensions. Requirements parameters can also be adapted to your adhesive application by selecting the appropriate adhesive tape.

We also offer many products for immediate delivery in our adhesive technology online shop. And if you need an individual, tailor-made adhesive solution, we are happy to be your competent adhesive expert at your side.

Integration of self-adhesive die-cut parts into the production process

In addition to functional adhesive tape properties, integrating adhesive processes into production workflows is a high priority. Self-adhesive tapes can be processed by hand or integrated into semi- or fully automated processes. However, self-adhesive tapes reach their processing limits in more complex process sequences, especially when it comes to material combinations, special shapes and/or single-piece feeding.

The perfect solution is self-adhesive die-cut parts, which have the same balanced performance data as the original adhesive tape, but offer additional rationalisation advantages thanks to their precise dimensions. This advantageous handling results in both time and cost savings in the subsequent processing steps. The production of a ready-to-use die-cut part requires not only high-quality raw materials but also extensive production experience.

The right material - material solutions from Steier, Germany

The structure, properties and performance characteristics of a self-adhesive tape are determined by the backing material and the respective adhesive system. Double-sided adhesive tapes enable a wide range of combinations that demonstrate both the technical feasibility and help determine the cost framework. In addition to material recommendations based on non-woven, film, fabric and foam carriers as well as acrylate foams, customised die-cut parts are manufactured according to your specifications and requirements. Material samples are available on request at any time.

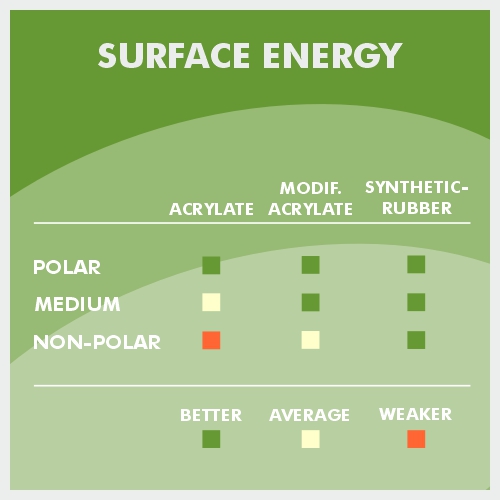

Adhesives and surfaces - a diverse selection

tesa® ACXplus acrylic foam adhesive tapes for the most demanding requirements

Structural bonds place the highest demands on self-adhesive tapes, especially in industrial and automotive applications. In many cases, mechanical fastening methods such as riveting, welding or screwing are not suitable for joining dissimilar materials such as glass, metal, plastic or paint. In addition to economic considerations, design requirements must also be taken into account in many cases. Only a high-performance adhesive tape can meet these visual requirements. To meet these requirements, we work with die-cut parts made from adhesive tapes from the tesa® ACXplus product family. We would be happy to support you in your individual applications with tesa® acrylic foam adhesive tapes.

Processing instructions - structural bonding with Steier, Germany

Low VOC: Low-emission interior applications

Low emissions of volatile organic compounds and the prevention of condensable emissions improve the air quality in vehicle interiors and prevent health irritations and allergies. Double-sided low-VOC adhesive tapes are used as fastening solutions for carpets, decorative elements, seals, shelves, trim, seat sensors or for fixing insulation materials to the front wall. This ensures compliance with the requirements of the VDA 278 standard.

Deutsch

Deutsch

English

English

© 2022 - 2026 Max Steier GmbH & Co. KG

© 2022 - 2026 Max Steier GmbH & Co. KG